For different parts of electric power tools, the bearings’ characteristics will vary accordingly as well. Take the angle grinders for example, the bearings in this application will mainly be divided into three parts: the bearings for fan end, the bearings for commutator end as well as the bearings for grinder output spindle. Check the details for these three applications as following:

Fan end

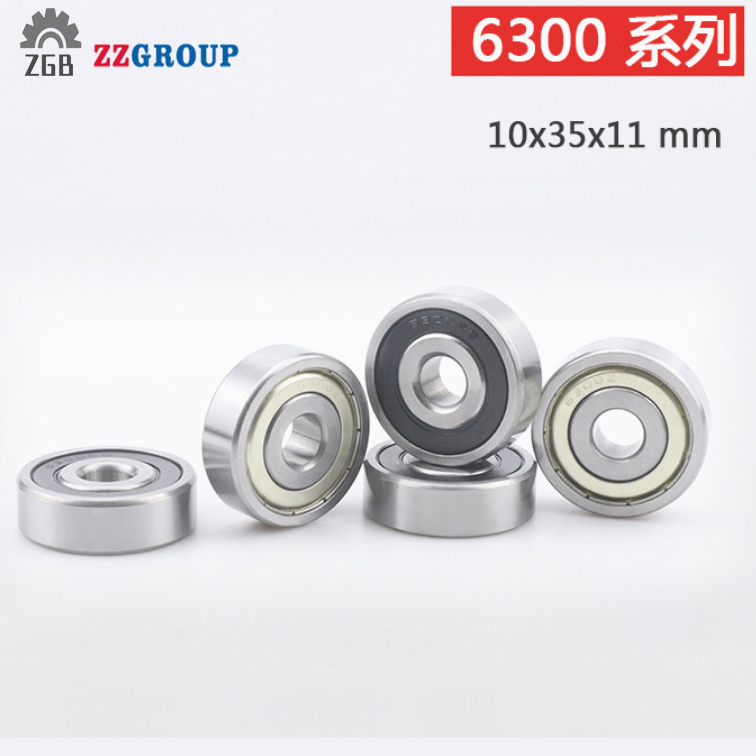

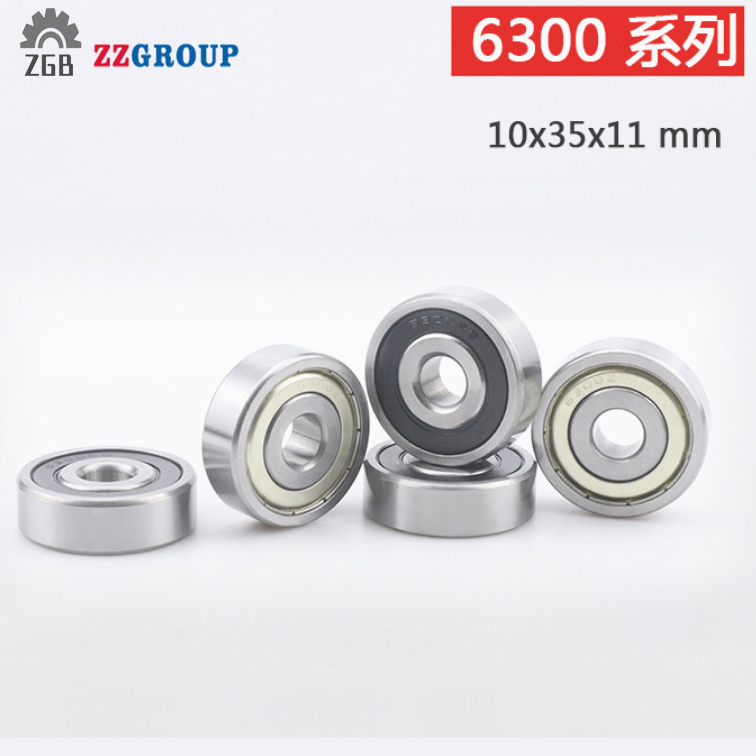

The bearing will need to cope with a combination of high speed, high temperature, heavy loads and a dusty environment.The ZGB solution is a single row deep groove ball bearing fitted with light contact Rubber seals or metal shields (the choice is dependant upon the environmental conditions). Special greases with high-speed capability and low grease leakage properties are used.

Commutator end

The bearing will need to cope with high speed, high temperatures and a dusty environment. The ZGB solution is a single row deep groove ball bearing fitted with light contacting rubber seals to ensure good dust resistance and high-speed capability. Special greases with high-speed capability and low grease leakage properties are used.

Grinder output spindle

On the tool side, bearings shall sustain the cutting loads (axial and radial), with risk of high misalignment in a dusty environment. ZGB bearings for this application are equipped with heavy contact rubber seals that ensure a very good resistance to pollution as well as special greases for high speed and low leakage performances. Also, our product range offers extra benefits to the manufacturers of electric power tools:

> High reliability and long life through proven product design, excellent material quality and production technology

> Reduced energy consumption due to special bearing solutions and lightweight design

> High power density due to space-saving solutions

> Safety in bearing selection through the proven knowledge of our application experts

> Customized solutions developed in close cooperation with the customer using the latest technologies and continuous further development

In all, ZGB understands your requirements for longer service life, no relubrication, low vibration, energy saving, low weight and low heat generation for electric power tools. ZGB high quality raw material with most advanced heat treatment technology as well as a range of optimized seals solutions are the major tools to optimize your applications.

In all, ZGB understands your requirements for longer service life, no relubrication, low vibration, energy saving, low weight and low heat generation for electric power tools. ZGB high quality raw material with most advanced heat treatment technology as well as a range of optimized seals solutions are the major tools to optimize your applications.

In all, ZGB understands your requirements for longer service life, no relubrication, low vibration, energy saving, low weight and low heat generation for electric power tools. ZGB high quality raw material with most advanced heat treatment technology as well as a range of optimized seals solutions are the major tools to optimize your applications.